Views: 0 Author: Site Editor Publish Time: 2024-03-05 Origin: Site

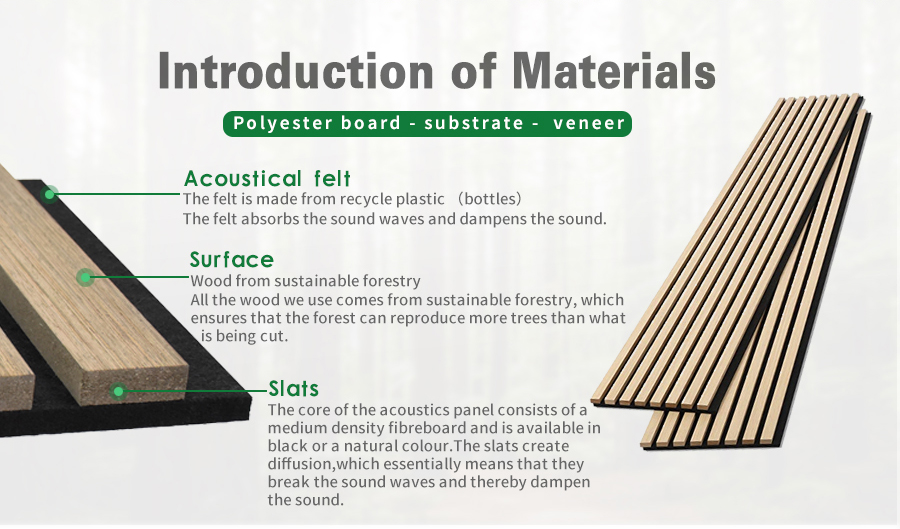

Wood slat PET acoustic panels are a composite material composed of polyester fiber board and wooden strips. Each panel is handmade which not only enhances the sense of decoration visual but also creates a quieter and more comfortable environment. The products use environmentally friendly materials and are certified by authoritative organizations.

This material combines the advantages of polyester fiberboard and the structural stability of wood strips, offering various excellent characteristics.

Durability and Stability: Polyester fiberboard exhibits high durability and stability, resisting moisture, swelling, or contraction even in environments with significant humidity changes.

Rot and Mold Resistance: Treated for rot and mold prevention, polyester wood strips maintain excellent resistance to fungi or corrosion, enabling prolonged use in damp conditions.

Ease of Processing: Compared to solid wood, polyester wood strips are more easily processed and shaped, allowing for cutting, drilling, nailing, or gluing as needed, enhancing versatility in construction and furniture applications.

Environmental Friendliness: Typically made from recycled or renewable materials, polyester wood strips demonstrate a degree of environmental friendliness, aligning with modern demands for sustainable development and environmental protection.

Aesthetic Appeal: Through surface treatments and decoration, polyester wood strips achieve an attractive appearance, mimicking the texture and grain of real wood to meet diverse decorative needs.

| Size | 600mm*2400/2700/3000mm |

| Pattern | 27-13/35-15 |

| Thickness | 12/15/18mm (MDF) +9mm (PET) |

| Surface | natural wood veneer , engineer wood veneer, melamine |

Hotel Lobby, Corridor, and Room Decoration

Polyester wood strips enhance the aesthetic appeal of hotel interiors, providing a durable and visually pleasing option for lobby and corridor decor. They can also be used to add warmth and sophistication to guest rooms.

Conference Halls

In conference halls, polyester wood strips contribute to a professional and elegant atmosphere. Their stability and resistance to moisture make them suitable for long-term use in high-traffic areas.

Schools

Polyester wood strips can be utilized in school interiors for both practical and aesthetic purposes. They offer a durable and low-maintenance option for classrooms, hallways, and common areas.

Recording Rooms and Studios

In recording environments, where acoustics are crucial, polyester wood strips can be used as acoustic panels. Their ease of processing allows for customization to meet specific sound absorption needs.

Residences

Within residential spaces, polyester wood strips can be applied for various purposes, including wall paneling, ceiling treatments, and furniture construction. Their aesthetic appeal adds warmth and character to homes.

Shopping Malls

Shopping malls benefit from the durability and aesthetic versatility of polyester wood strips. They can be incorporated into interior design elements such as wall cladding, storefronts, and display fixtures.

Surface Preparation:

Ensure the surface is clean, dry, and smooth before installation.

Address any structural issues or irregularities on the substrate.

Layout Planning:

Plan the layout to optimize the visual appeal of the wood strips.

Consider starting from the center or focal point for balanced installation.

Adhesive Application:

Use a recommended adhesive suitable for wood and the substrate.

Apply the adhesive evenly on the back of the wood strips.

Positioning and Securing:

Press the wood strips firmly onto the substrate, aligning them according to the planned layout.

Secure the strips in place using recommended fastening methods if required.

Curing and Setting Time:

Allow sufficient time for the adhesive to cure and the wood strips to set firmly in place before subjecting them to heavy use.

Maintenance Tips:

Clean the surface regularly using appropriate cleaning agents.

Avoid harsh chemicals that may damage the material.

In the polyester wood strips industry, technological innovation and development trends are crucial aspects.

Some key points include:

Improvement of Production Processes: The industry is committed to developing more efficient and energy-saving production processes to increase production efficiency and reduce production costs.

Enhancement of Material Properties: Researchers and manufacturers are striving to improve the physical and chemical properties of polyester wood strips to better meet the needs of different applications, such as strength, weather resistance, and flame retardancy.

Expansion of Application Areas: The industry is exploring new application areas, such as more extensive use in construction for both structural and decorative purposes or creating innovative applications in other fields.

Development of Biodegradable Materials: With increasing environmental concerns, the polyester wood strips industry may invest more resources in researching biodegradable materials to reduce environmental impact.

Smart Manufacturing: Introducing smart technologies such as the Internet of Things and data analytics to optimize the production process, improve quality control, and achieve more intelligent manufacturing.

These technological innovations and trends will drive the polyester wood strips industry towards a more advanced, sustainable, and diversified direction.

Contact Us to Get the Free Samples!