Views: 0 Author: Site Editor Publish Time: 2025-06-17 Origin: Site

As our world becomes increasingly urbanized and interconnected, noise pollution has escalated into a critical environmental and health concern. Whether in residential developments, commercial spaces, or industrial environments, the demand for materials that effectively minimize sound transmission is higher than ever before. Enter Mass Loaded Vinyl (MLV)—a high-performance noise control material designed to meet these demands by offering an ideal combination of mass, flexibility, and ease of installation.

Mass Loaded Vinyl has emerged as a preferred solution across industries that require superior soundproofing: from high-end home cinemas to industrial plants and office buildings. Its unique properties make it a versatile, long-lasting, and cost-effective choice for noise reduction solutions.

Why Uniform Mass Matters

The effectiveness of any soundproofing material relies heavily on its mass, and Mass Loaded Vinyl (MLV) is no exception. According to acoustic principles, the denser a material, the better it is at impeding the transmission of sound waves—especially low-frequency airborne noise. MLV is engineered specifically with this in mind. It generally ranges from 1 to 2 pounds per square foot (psf), providing a carefully balanced weight that delivers optimal sound insulation without being overly bulky or difficult to install.

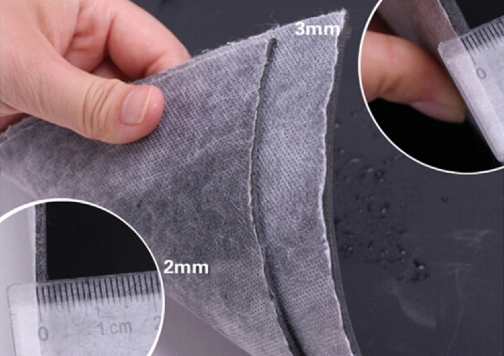

Uniform mass across the entire sheet is critical. Every square inch of MLV must deliver consistent sound-blocking performance, especially when used in walls, ceilings, floors, or acoustic panels. A consistent density ensures that the barrier has no "weak spots" where sound could leak through. This evenness in material composition contributes directly to a higher Sound Transmission Class (STC) rating and overall acoustic performance.

Consequences of Inconsistent Mass

In MLV, even slight deviations in weight or thickness can compromise the material’s ability to block sound. If parts of a vinyl sheet are thinner or less dense due to manufacturing defects or poor quality control, sound can pass through those areas more easily. These inconsistencies significantly reduce the STC rating of the entire barrier system.

For instance, in a commercial office or home studio where privacy and noise control are essential, these weak points can result in sound leakage that defeats the purpose of installing soundproofing in the first place. This is why reliable mass per square foot isn’t just a technical detail—it’s a core performance factor.

Need for Reliable Product Specifications

To ensure effective sound control, always select MLV that comes with verified specifications and third-party acoustic test reports. Trusted manufacturers clearly document their MLV’s weight, thickness, and performance ratings, often including certifications that confirm consistency and quality.

When evaluating MLV products, look for materials with precise and consistent manufacturing standards. This attention to detail not only improves soundproofing but also makes the installation process more predictable and efficient. Choosing high-grade MLV with verified specs ensures you get the noise reduction performance you expect—every time.

Flexibility Prevents Tearing and Damage

Despite its substantial mass, Mass Loaded Vinyl (MLV) is remarkably flexible and user-friendly, a quality that makes it one of the most adaptable soundproofing solutions on the market. This flexibility means MLV can be rolled, folded, cut, or bent without tearing or losing structural performance. Unlike rigid panels or brittle foam barriers that can crack or break under pressure, MLV conforms to the installer’s needs while preserving its acoustic properties.

This attribute is particularly useful in construction or renovation environments where surfaces aren’t always flat or regular. Installers can confidently wrap MLV around joists, wall frames, conduit pipes, and oddly-shaped architectural features. Even after repeated handling or repositioning during installation, high-grade MLV maintains its integrity—reducing material waste and installation time.

Adapting to Curved Surfaces and Tight Installations

One of MLV’s standout advantages is its versatility in tight or curved spaces. From winding HVAC ductwork and exposed columns to arched ceilings or complex retrofit projects, MLV bends and shapes easily without compromising its density or sound-blocking performance. Its flexible nature ensures a snug fit, allowing for continuous acoustic coverage without gaps or loose edges—both critical for maintaining effective noise control.

In historic building renovations or modern designs that include circular walls or decorative structures, rigid acoustic materials often fall short. MLV, on the other hand, molds seamlessly to these challenging surfaces, allowing builders and designers to achieve both functional and aesthetic goals.

Withstanding Harsh Environments and Mechanical Load

Mass Loaded Vinyl is not only flexible but also highly durable. Quality MLV products are designed to withstand rough handling, temperature changes, humidity, and ongoing mechanical stress without degrading. They’re tough enough to endure foot traffic during construction, resist accidental punctures from tools, and hold their form over time even in vibration-prone settings like machine rooms or industrial sites.

This durability ensures long-term performance, making MLV a reliable option for permanent installations in both commercial and residential buildings. Whether you’re installing it in an attic, basement, office, or industrial facility, MLV holds up under pressure—delivering lasting soundproofing results that don’t fade with time.

Mass Loaded Vinyl is best known for interior use, but certain high-grade versions are engineered specifically for outdoor applications. These weather-resistant MLV products can withstand UV exposure and moisture without degrading. Whether applied to outdoor equipment enclosures, external walls, or rooftop installations, these variations maintain acoustic performance while resisting environmental wear.

The adaptability of MLV extends into heavy-duty sectors:

Industrial Applications: Factories, workshops, and power plants benefit from reduced equipment and machinery noise when MLV is used as an enclosure layer.

Environmental Noise Barriers: MLV can be combined with custom fence designs or roadside barriers to minimize traffic impact on nearby properties.

Commercial and Office Settings: Retail shops, cafes, and office suites leverage MLV to keep ambient sound at bay, maintaining crisp acoustics and wellbeing.

Mass Loaded Vinyl can be paired with other acoustic components—such as panels, foam, and ceiling tiles—to create multifunctional sound control systems. It can serve as the mass layer in floating wall systems, sound blankets, or interior mobile sound barriers, enhancing overall attenuation across multiple frequency ranges.

Off-the-shelf or economy MLV products—especially those with low density or thin vinyl—can be prone to tearing. Worse still, inconsistent mass distribution can drastically reduce acoustic performance. Investing in high-grade MLV not only ensures soundproofing success but also ensures safety and warranty compliance in commercial applications.

Leading MLV products undergo rigorous quality control and are built to maintain tensile integrity under load. This prevents roll edge splitting, tearing, and dropping—maintaining airtight sealing essential for acoustic barrier systems.

Premium manufacturers often provide detailed documentation, fire ratings, and performance warranties. This gives contractors and property owners confidence in the product’s longevity, as well as compliance with building codes and safety regulations. With proper installation, MLV systems can last for decades with minimal maintenance.

In summary, Mass Loaded Vinyl offers unmatched consistency, flexibility, and durability, making it a top choice for soundproofing across residential, commercial, and industrial environments. Whether you're tackling noise issues in a home theater, office space, or factory floor, high-quality MLV ensures long-term acoustic performance and regulatory compliance.

For the best results, trust a reputable supplier. MQ Acoustic Materials Company specializes in premium MLV products designed to meet strict quality standards. Their expert team can help you select the right solution for your specific project needs.

Visit MQ Acoustic Materials today or get in touch to explore how their soundproofing solutions can enhance your next build or renovation.